In the world of industrial packaging and logistics, the humble pallet plays a mighty role. But what holds these pallets together, ensuring they can bear heavy loads and endure rough handling across continents? The answer: coil nails.

At Whitworth Engineers, we specialise in manufacturing and exporting high-performance coil nails that power pallet manufacturing across the globe, from the USA and Canada to Europe and the Middle East. Let’s explore why coil nails are essential to pallet production and how choosing the right supplier can drastically impact your bottom line.

Why Are Coil Nails Crucial for Pallet Manufacturing?

1. High-Speed Production Efficiency

Pallet production lines require fast, repetitive fastening to maintain output targets. Coil nails, loaded into nail guns, allow for thousands of nails to be driven with minimal downtime for reloading — a must-have for high-volume operations.

2. Strong and Reliable Joints

Coil nails offer deep penetration and strong holding power, ensuring each pallet can withstand stacking, shipping, and heavy-duty industrial use. With consistent shank diameters and sharp tips, Whitworth’s coil nails deliver unmatched reliability.

3. Lower Breakdown Rates

Using high-quality coil nails reduces jamming and misfires in nailers — leading to less downtime, fewer tool repairs, and better overall productivity on the shop floor.

🌍 The Global Demand for Quality Coil Nails

With the exponential growth in e-commerce, logistics, and global shipping, pallet demand has surged. But so has the expectation for stronger, longer-lasting pallets — making coil nails more critical than ever.

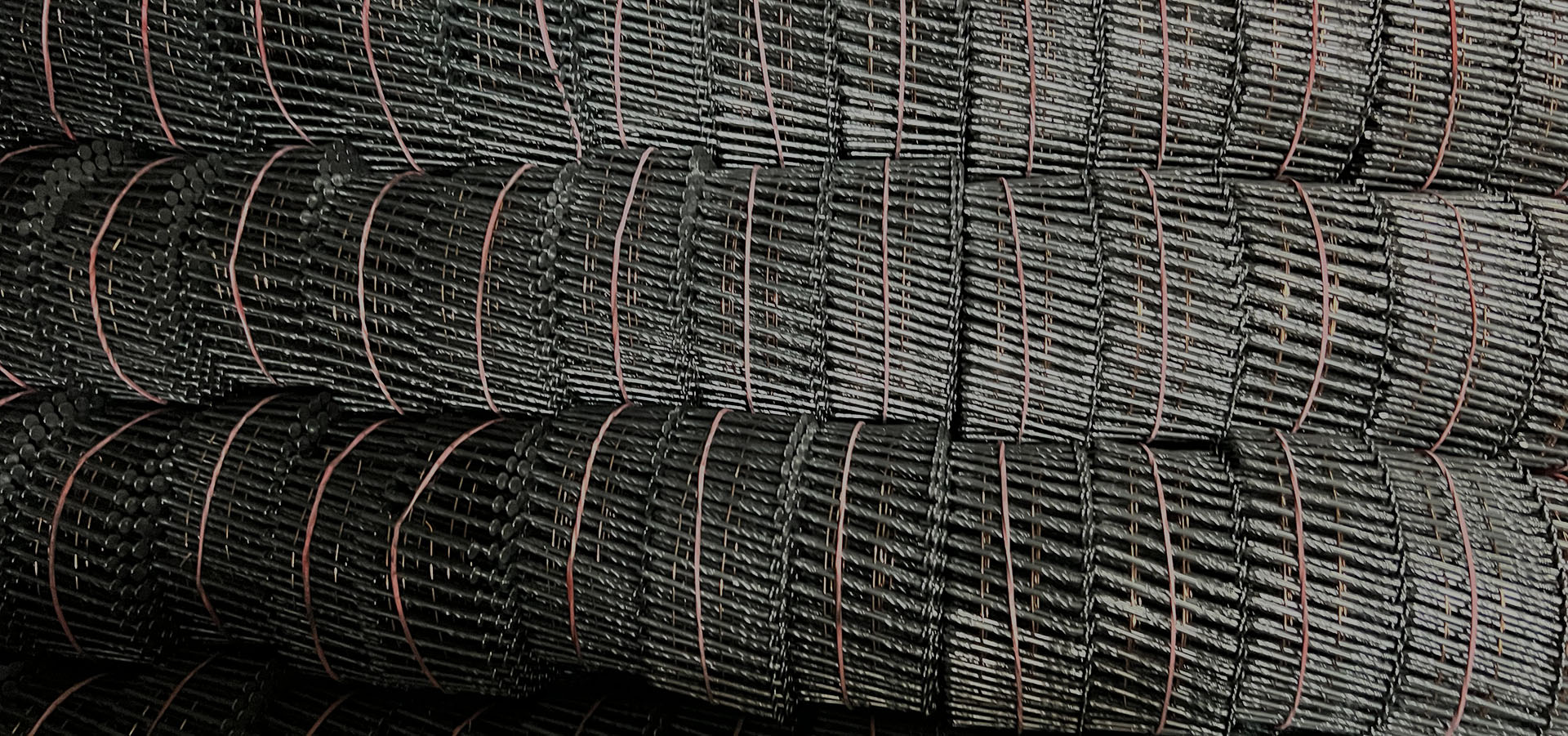

At Whitworth Engineers, our coil nails are precision-manufactured on state-of-the-art cold headers and automated winding lines. Whether you’re building hardwood export pallets in the US or lightweight pine-based pallets in the Middle East, our nails adapt to your application needs.

💡 Choosing the Right Coil Nail for Your Pallet Line

When selecting coil nails for your production unit, consider the following:

- Shank Type: Smooth, ring, or screw shank depending on wood hardness

- Length and Diameter: Custom sizes from 1″ to 5″ and diameters from 2.0mm to 3.8mm

- Winding Type: Conical or flat coil depending on your tool and loading preferences

- Galvanization: Choose EG-coated or bright finish based on corrosion resistance needs

✅ Why Leading Pallet Makers Trust Whitworth Coil Nails

- Consistent Quality: Uniform wire drawing and high-speed welding ensure reliable performance

- Custom Sizes Available: Engineered for your exact fastening needs

- Global Export Expertise: Seamless delivery to USA, UK, Canada, UAE, and beyond

- Lower Cost Per Nail: Optimized production = competitive pricing without compromising quality

📈 Boost Your Pallet Production with Whitworth Coil Nails

If you’re a pallet manufacturer, distributor, or fastener reseller, it’s time to partner with a coil nail supplier that delivers performance, consistency, and global supply strength.

👉 Get in touch with Whitworth Engineers to request a sample or pricing for your region. Let us help you build stronger pallets — one coil at a time.

Comments