Whitworth Engineers is one of the leading coil nail manufacturers and exporters in India. Our coil nails are trusted across Hyderabad and beyond for their strength and precision. Whether you're searching for smooth, ring, or screw shank nails — we've got you covered.

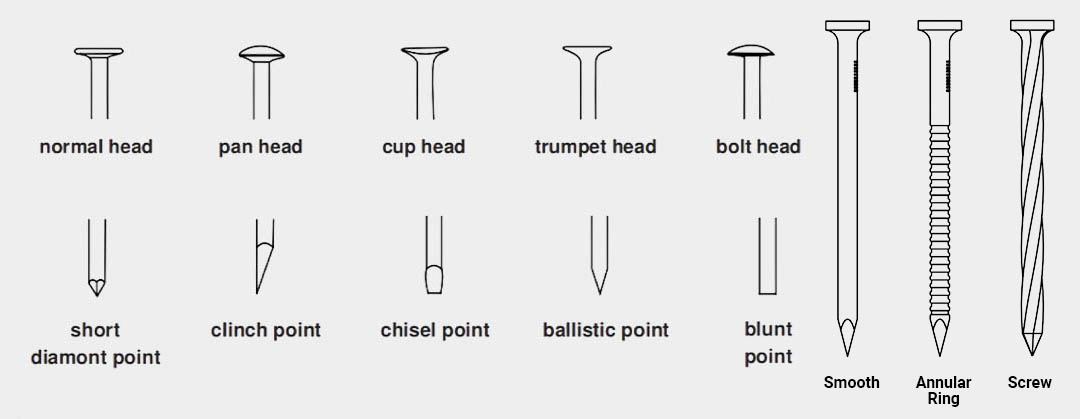

A nail consists of a Head, Shank and the Tip. The most important part of the coil nail is the shank which essentially carries the impact force.

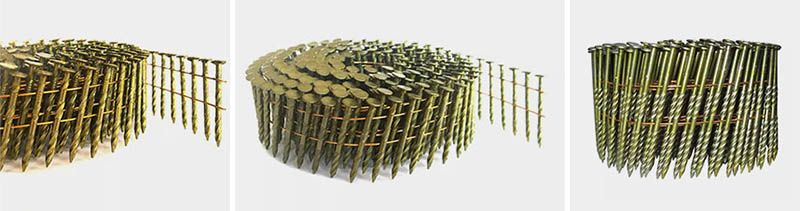

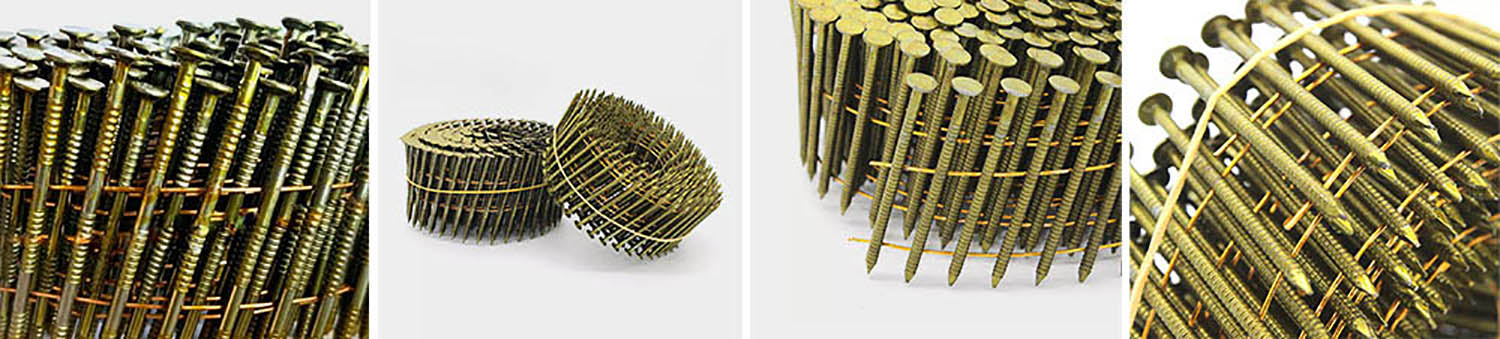

A coil nail comprises of a series of identical sized nails evenly spaced and spot welded at two defined points on each nail to form a chain of nails which is then wound on its central axis to form a roll. This roll is loaded in a Nail Gun or coil nailer, where each nail is driven into the wood for making wood pallets, wooden crates, boxes.

These Coil Nails have different surface protection depending upon the environment in which they are required to be used and can have a bright vinyl coating, electro galvanizing and hot dipped galvanizing. In extreme situations like saline or highly moist places, stainless steel coil nails are used.

Depending upon the type of nail shank, tip and surface coating, there are smooth shank, ring shank or screw shank coils with diamond, blunt point with bright, electro galvanized or hot dipped coil nails.

Coil Nails have nails ranging from 375 nails per roll to 125 nails depending upon the size of the nail. These Coil Nails are used in regular nail guns.

Most common profile is the smooth shank. The nail is completely smooth for easy penetration into even the hardest of woods.

In a Ring Shank Profile, a series of concentric ring formations are made along the nail shank one below the other. These rings grip the wood fibres once the nail is embedded into the wood in its final position and prevent it from getting disturbed.

There are certain applications wherein the pallets are made on automatic pallet making machines. In such machines, multiple nail guns are prefixed and operate collectively. Such nail guns need to operate continuously without stoppage. To meet this condition, we offer Jumbo Coils. These Jumbo Coils comprise nails from 900 pieces in each roll to 3000 pieces. These are totally customised and are made to specified requirement. While the nail specifications are the same as regular coils, difference is only in the number of nails per roll. Nail guns which handle such Jumbo Coils usually do not have a magazine like the regular nail guns and operate on a base plate.

Nail head is generally round in shape with the surface either flat, chequered or countersunk.

A Flat head Coil Nails generally have a smooth surface and is of different sizes depending upon the application for which it is made. Normal head Coil nails are used for general wooden box, pallet manufacturing applications. A wider head nail would find applications in the roofing wherein the sheets are held in place due to the wider head profiles.

A chequered head Coil Nail consists of small diamond shaped formations along the head surface. These diamond shaped formations give a better grip when they are struck with a hammer and prevent slippage.

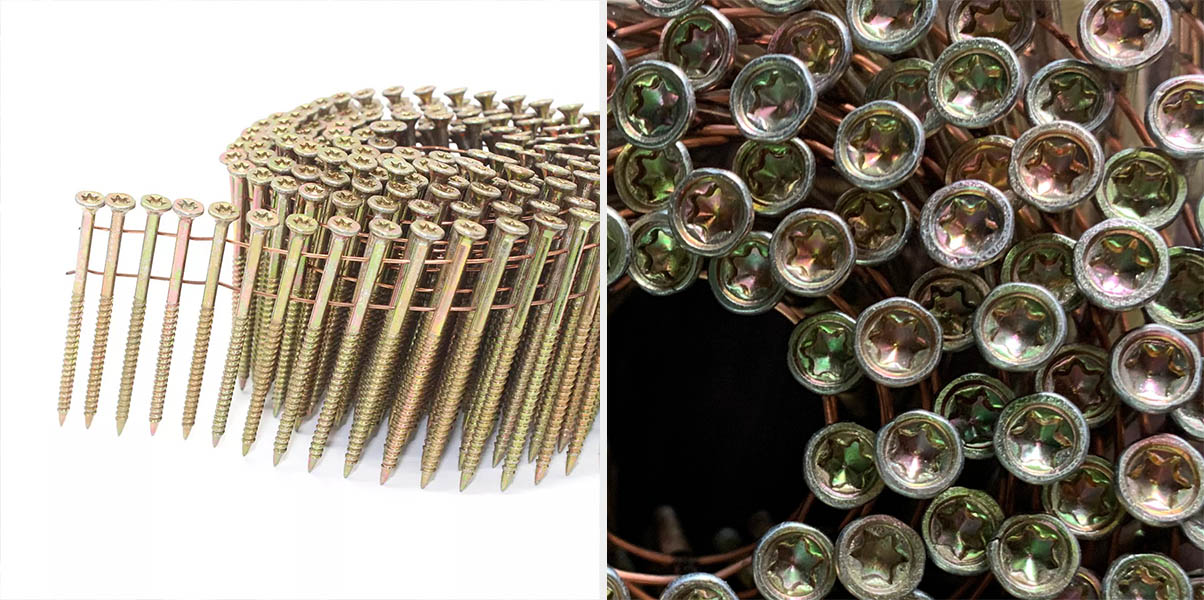

A countersunk head Coil Nail is a funnel shaped head formation with different formations on the head surface for easy removal after being driven in. These nails have applications in the furniture industry and sink into the wood such that the nail head surface is flush with the wood surface. The different types of formations are :

A hexagonal socket in the head: TORX HEAD: these nails can be removed from the wood with an Allen key.

A Philips socket in the head: PHILIPS HEAD: these nails can be removed with a star screwdriver.

These nails are a replacement for wooden screws which are not only expensive but also take time to drive into the wood and removal.

Diamond Point is generally used for common applications where wood splitting is not an issue of contention. The diamond point is either sharp or slightly rounded to reduce the piercing impact on the wood.

Diamond point with a very short tip completely rounded off is a Blunt point and used in hard woods to avoid splitting.