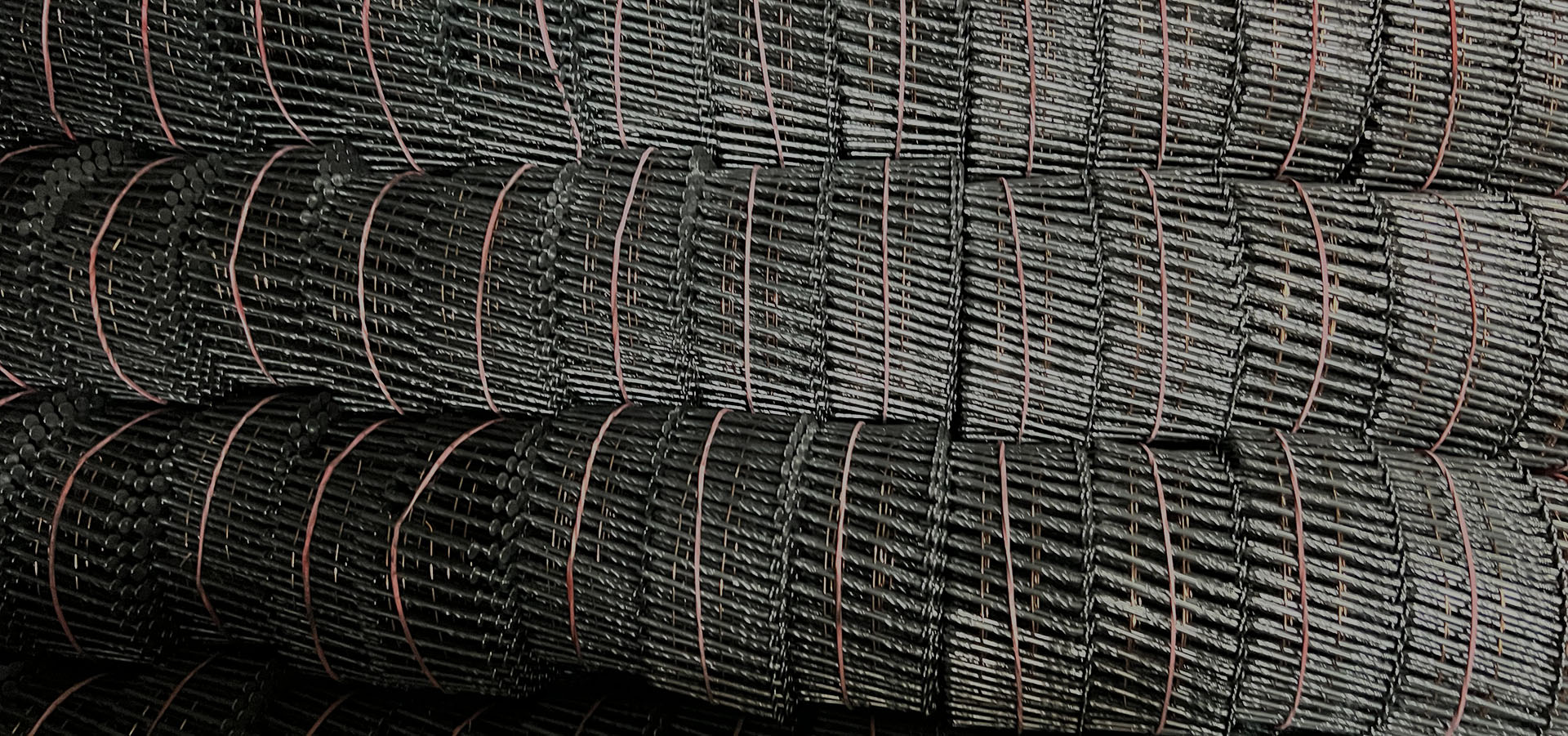

When people think of nails, they often picture a toolbox essential. But coil nails? These are the silent workhorses behind some of the world’s most heavy-duty industrial applications.

At Whitworth Engineers, we manufacture and export precision-engineered coil nails that power operations across multiple sectors. From high-speed assembly lines to rugged construction sites, coil nails are everywhere — even if they go unnoticed.

Here are 5 industries that rely on coil nails every single day, and how we’re helping each one build faster, stronger, and smarter.

1. Construction Industry

➤ Application:

Framing, roofing, sheathing, fencing, decking — all demand strong, consistent, high-penetration nails.

➤ Why Coil Nails?

Coil nails enable rapid-fire nailing through pneumatic guns, drastically improving labor efficiency on-site. Ring shank and screw shank variants offer extra grip in structural applications.

➤ How Whitworth Supports:

- Full range of smooth, ring, and screw shank nails

- Anti-corrosion EG coating for outdoor durability

- Custom sizes from 2” to 5” and beyond

2. Packaging & Crating Industry

➤ Application:

Manufacturing wooden crates, boxes, and protective skids for industrial shipping and storage.

➤ Why Coil Nails?

Packaging needs speed and strength. Coil nails provide dense, fast driving without splitting thin wood, making them ideal for high-volume crate production.

➤ How Whitworth Supports:

- Bright and EG-coated options

- High-speed nail feeding coils compatible with automated systems

- Export-ready bulk or branded packaging

3. Pallet Manufacturing

➤ Application:

Pallets are the foundation of global supply chains, and every one needs dozens of nails to stay intact.

➤ Why Coil Nails?

Coil nails allow automated, high-speed nailing, essential in factories churning out hundreds of pallets per day.

➤ How Whitworth Supports:

- Nails tailored for pine, hardwood, or composite pallets

- Low-jam coils that reduce downtime

- Ability to customize coils for regional pallet standards

4. Furniture Manufacturing

➤ Application:

Stapling and nailing of wooden frames, back panels, armrests, and internal structures.

➤ Why Coil Nails?

In furniture, appearance and integrity matter. Coil nails offer clean, flush finishes and strong holding power for structural parts — while keeping production fast.

➤ How Whitworth Supports:

- Fine wire coil nails for delicate joints

- Smooth finish for decorative woods

- Custom loads for compact furniture-grade nailers

5. Prefab & Modular Building Units

➤ Application:

Modular homes, wall panels, roofing trusses — all require repeatable fastening solutions that maintain strength across hundreds of units.

➤ Why Coil Nails?

Prefab construction runs on assembly-line precision. Coil nails provide the speed and consistency needed for these volume-driven environments.

➤ How Whitworth Supports:

- Coil nails in custom lengths and diameters for wall panels

- OEM partnerships for tool compatibility

- Fast export service to global modular unit builders

Why Industry Leaders Trust Whitworth Engineers

- ISO 9001:2015 certified coil nail production

- Over 150,000 coils/month capacity, scaling to 450,000

- Proven performance in the USA, Canada, Europe, and the Middle East

Let’s Nail Your Next Project

Whether you’re a pallet manufacturer in Chicago, a crate builder in Dubai, or a construction supplier in Ontario, Whitworth Engineers delivers the coil nails your industry runs on — quickly, affordably, and reliably.

Request a quote or free sample today. Let’s build something better, together.

Comments