Leaders in Nailing Systems

In the world of coil nails, not all products are created equal. At Whitworth Engineers, we believe that excellence lies in engineering — not just in mass production. Every nail that leaves our facility is the result of precise material selection, controlled tolerances, and disciplined processing.

Whether you’re in the construction, pallet, furniture, or crate manufacturing industry, the performance of your tools — and the durability of your output — depends on the quality of the coil nails you use.

Here’s a deep dive into the engineering processes that make Whitworth Coil Nails globally trusted.

1. Raw Material Matters: High-Carbon Wire Rods

We start with IS-standard high-carbon steel wire rods, specifically selected for:

- Tensile strength

- Formability

- Surface consistency

Our sourcing ensures that every batch provides the ductility required for heading and the hardness needed for penetration — critical for both automated nailing and end-use strength.

2. Precision Wire Drawing

Our 5-unit in-house wire drawing line maintains tight drawing tolerances using:

- Carbide dies for dimensional consistency

- Online diameter checks to ensure uniformity

- Surface cleaning and lubrication for downstream compatibility

Tolerance achieved: ±0.02mm — ensuring your nailer runs without jamming or misfires.

3. Controlled Polishing for Clean Feed and Longevity

We use vibratory polishing machines to eliminate:

- Sharp burrs

- Surface oxides

- Drawing lubricants

Polished nails result in:

- Smooth feeding in high-speed coil nailers

- Reduced wear on pneumatic tools

- Improved visual finish for exposed or semi-visible applications

4. Cold Heading and Shank Consistency

Our high-speed cold nail headers are calibrated for:

- Accurate head formation

- Uniform point shaping

- Minimal bend ratio

This allows us to produce millions of nails with identical specifications, crucial for large-scale industrial applications.

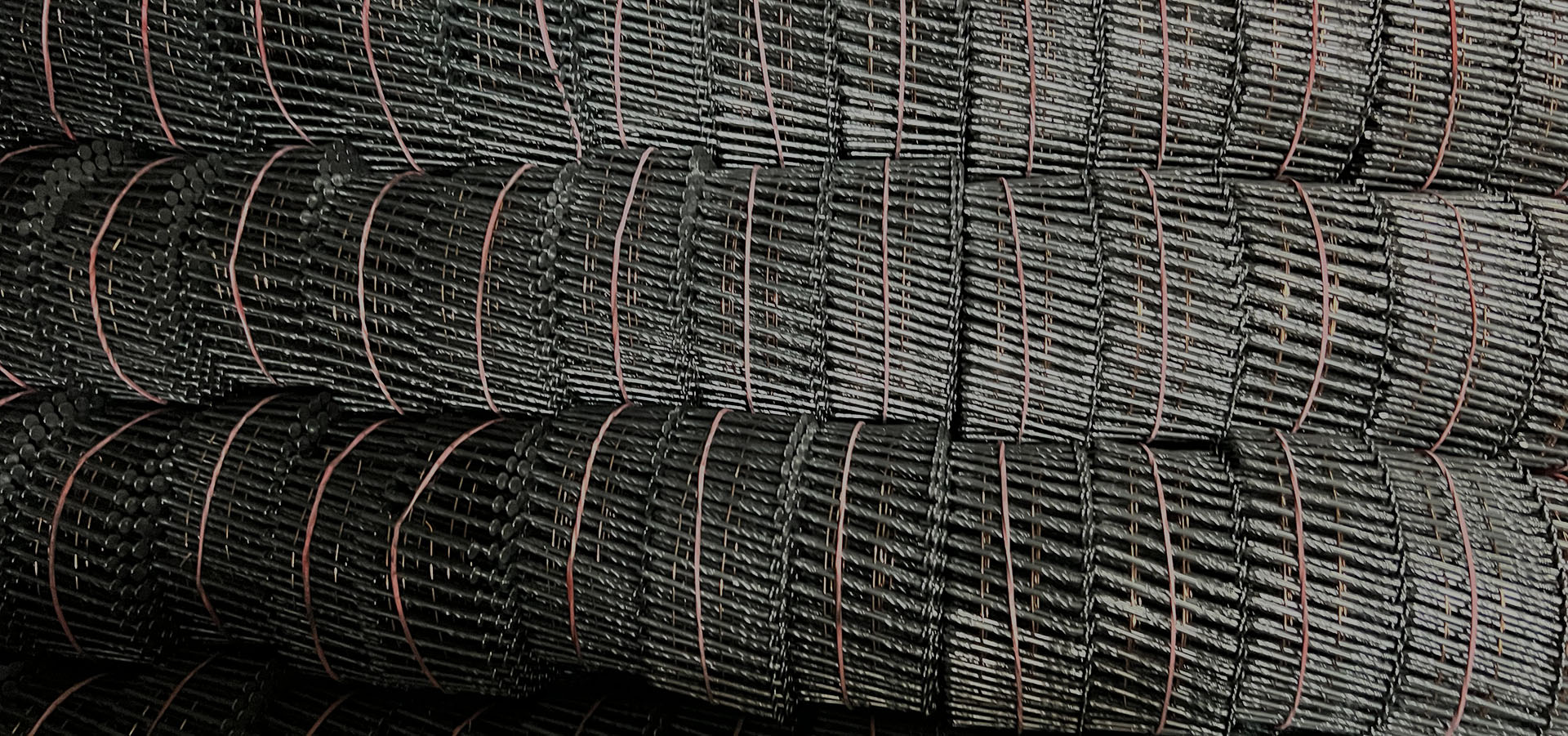

5. Automated Coil Welding

Whitworth’s nail collation lines use high-speed welding transformers:

- Consistent weld pitch ensures smooth coiling

- Precise nail angles (15°–16° standard for conical coils)

- Durable wire welding prevents coil loosening during shipping

Result: Coils that feed seamlessly — even in automatic high-capacity nailing systems.

6. Corrosion Protection: Bright Finish or EG Coating

We offer:

- Bright Finish: For indoor applications

- Electro-Galvanized (EG) Coating: For light corrosion resistance in semi-exposed environments

Coating adhesion, thickness, and uniformity are quality-checked to meet international export requirements — especially for markets like the USA, Europe, and the Middle East.

7. Quality Testing at Every Stage

- Dimensional checks on drawn wire and final nails

- Pull-out and bend testing for mechanical strength

- Nail jamming tests in real nailers before packaging

- Weight accuracy to meet declared coil counts

Why It Matters to You

If you’re a manufacturer relying on nail-fed systems, every minute lost to a jam or breakdown costs money. Whitworth Coil Nails are engineered to:

- Minimize tool downtime

- Maximize fastening consistency

- Extend nail gun service life

- Reduce total cost per nail driven

Whitworth = Engineering-Backed Reliability

From wire to weld, every nail is produced under strict ISO 9001:2015 certified processes. It’s not just about how many nails we make — it’s how well each one works for your production.

Interested in testing Whitworth Coil Nails for your application?

We’re happy to provide custom samples or fulfill bulk export orders tailored to your specs.

Comments