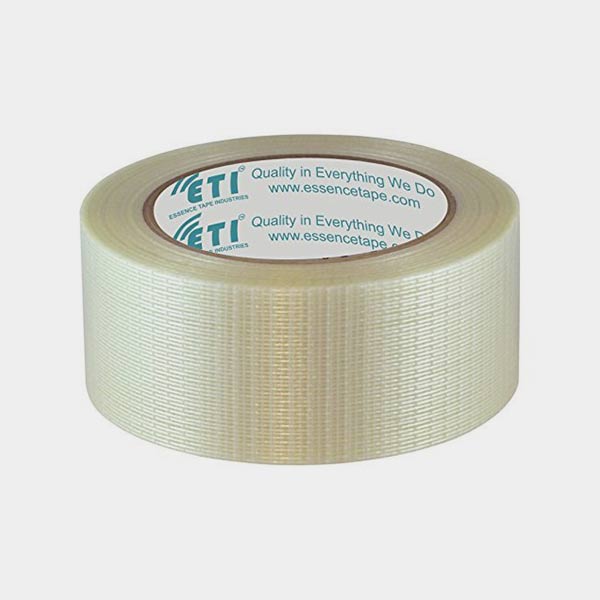

| Parametrs | Unit | Specification |

|---|---|---|

| Appearance | - | Evenly Coated |

| Shade | - | Trn/Color |

| Peel Adhesion | Gm/25mm | 1700-1900 |

| Breaking Strength | Kg/25mm | 35-40 |

| Elongation | % | 10-12 |

| Total Grammage | GSM | 110-115 |

| Adhesive Type | - | Hot Melt |

| Rolling Ball Tack | CMS | 8-10 |

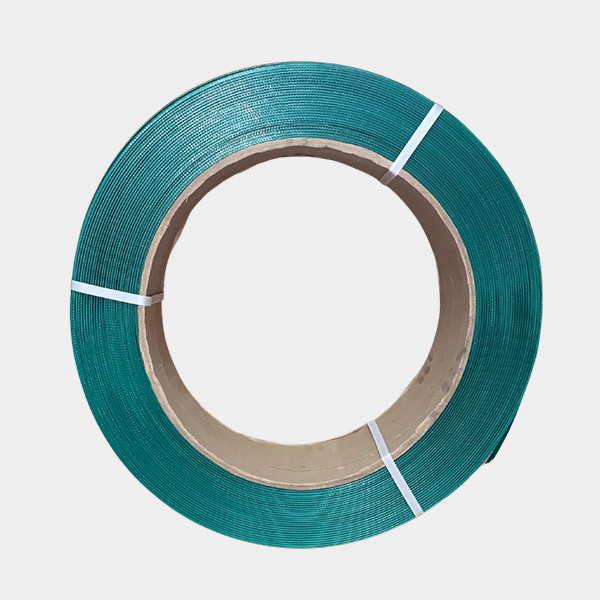

What is PVC Tape, PVC Electrical Tape?

PVC tape and PVC electrical tape is manufactured from standard and premium quality plasticised polyvinyl chloride (PVC), coated with an aggressive pressure sensitive adhesive allowing for adhesion on many different surface types including rough and tough to stick to environments.

Markets for PVC Tape, PVC Electrical Tape

PVC tape and PVC electrical tape is used extensively within the many automotive, construction, electrical wire harness, printing and graphics and specialty assembly sub-markets, including:

- Good conformability for easy and simplified applications

- Excellent electrical application

- Excellent resistance to abrasion, corrosion and moisture

- High grade adhesion

- Good sealing properties

- High dielectric strength and good mechanical protection

- Self-extinguishing properties

- Available in a wide range of colours for easy identification

- Conforms to RohS when ideal environmental safety is a concern

- IMQ and VDE approval certificates according to International Electrotechnical Commission